Inventory with NFC

Inventory with NFC

Inventory is a process that every company has to deal with. An inventory is an inventory that must be documented by a company through a directory. These can be tangible goods, such as a desk chair or a computer - but also intangible goods, such as rights and services (e.g. licenses as part of license management). By documenting the actual inventory, it is possible to calculate and estimate the value of the inventory at the end of a year. In this way it can be proven that debts and assets actually exist. Assets are measured within the inventory by counting, measuring or weighing.

The administration takes place depending on the organization. The divisions can be divided into different departments, depending on the size of the company. The personnel department, for example, is responsible for the work equipment provided, the IT department takes care of electronic data processing - the EDP devices. The accounting department is responsible for the administration of fixed assets and office management. What such an administrative process can look like and how NFC can help with the inventory is explained below.

Challenges of the inventory

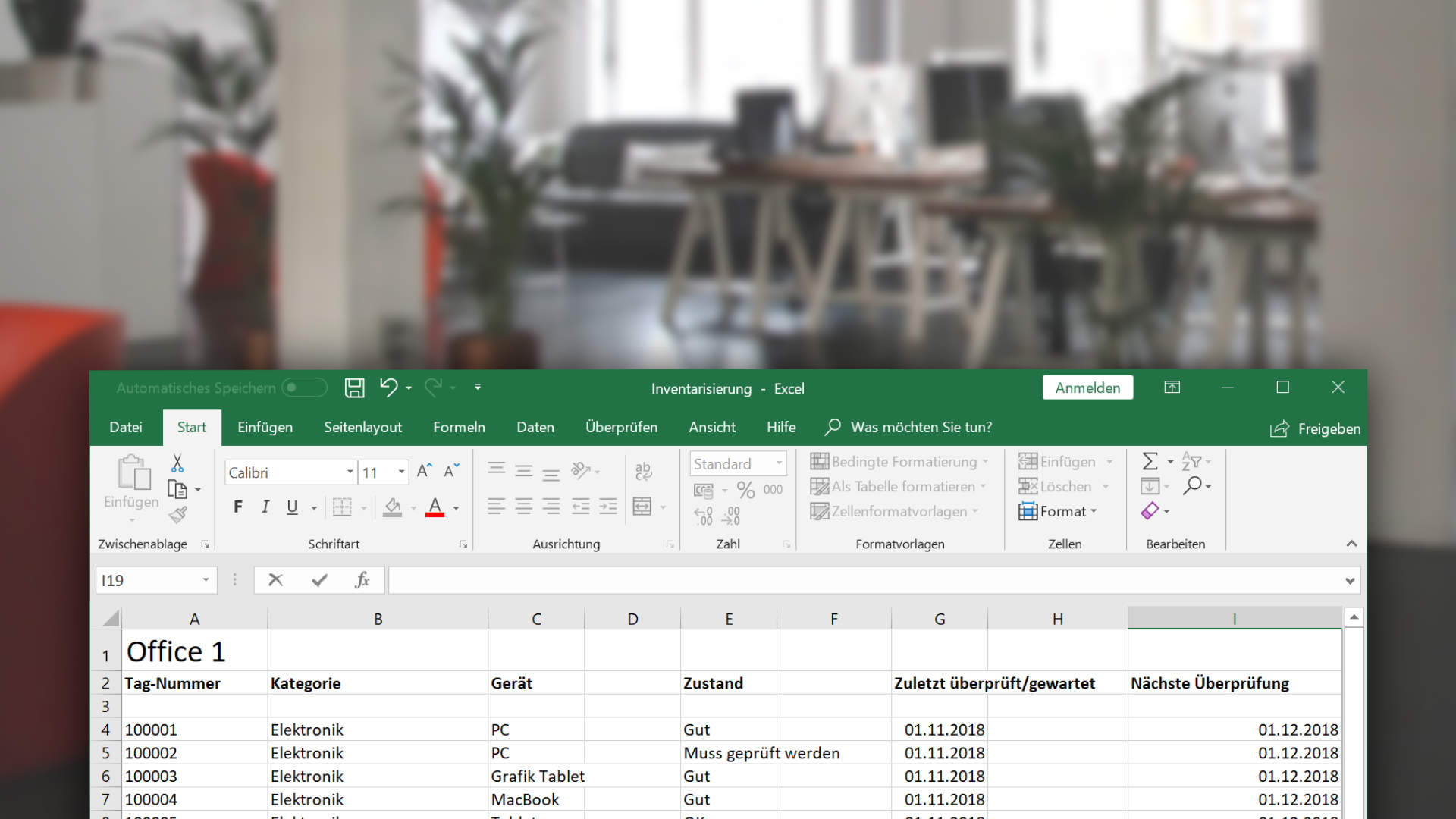

The inventory is usually done manually. In the first step, rooms and buildings of the company are recorded in which the inventory goods are located. A room plan or a floor plan can help to visualize and plan the procedure. Especially in large companies, this can provide a first rough overview of the current inventory. In the next step, the inventory items can be entered using a table. Predefined input fields for the location, group or category of the respective object can be a support during the data collection. It is important to maintain a structure that does not allow room for data loss. By using a table, all inventory items can be described precisely so that they are visually recognizable during the inventory and can be checked off manually afterwards. This makes it possible to access the stored inventories immediately.

However, a great challenge in the inventory process is to keep the inventory up-to-date. The created table must be updated again and again during the inventory. Furthermore, it must be possible to access the documented inventory items when checking the data. A clear allocation of the individual objects is essential. This is especially true for items that are used by several employees. One solution to master this challenge without additional complications is to use NFC technology.

Optimization of inventory processes through NFC

NFC tags can be a helper in inventory as they contain serial numbers (UIDs). For example, if you use NFC tags in the form of stickers, it is possible to clearly identify inventory items. The smartphone can then be used to read the NFC tags quickly and easily - without the addition of other devices. The use of NFC tags consequently provides a large overview for the inventory. Structuring and documentation are simplified by this process. NFC tags can store the data of an inventory item and uniquely describe it offline. In addition to object names, however, details of invoices and/or other object-specific information necessary for the inventory can also be described. In addition to direct storage in the chip, it is also possible to create a link to an online profile. This means that inventory objects can be characterized more closely by an online profile. For example, objects that look the same can be easily distinguished in the online profile by NFC tags. This link also makes it possible to create a central collection of all inventory items. All data and information is thus visible at a glance and can be individually retrieved.

In summary, it is clear that inventory taking and the central administration of inventories can be time-consuming - but are essential for individual companies to understand the value of inventory items. NFC can simplify this process by exploiting the uniqueness of NFC tags. They can store individual data and information, for example in the form of stickers, which can then be read from a smartphone