NFC for use in potentially explosive atmospheres

Explosion protection certification for ATEX zones

The handling and storage of flammable substances is a daily business in certain industrial segments, so there is a risk of explosion in many working environments. Consequently, explosion protection must be ensured with foresight, especially by the employer, and must be checked regularly in order to avoid personal injury and loss of production.

In this article, we will first summarize the issue of explosion hazards when working with electronic equipment as a potential ignition source, and then examine the topic of NFC from this perspective.

Explosion hazard in industrial working environments

An explosion hazard exists if an explosive mixture of air and flammable substances forms which can be ignited. Explosive mixtures can occur, for example, when flammable liquids / gases are processed, construction chemicals are used, or simply due to certain dusts. In combination with atmospheric oxygen and a potential ignition source, a fire or explosion can then occur. Areas with such environmental conditions are called ATEX areas. Equipment, components and protective systems must therefore comply with a number of regulations, standards and directives, taking into account the ATEX Directive 2014/34/EU.

Electronic devices as ignition source

A fire or explosion can occur if three basic conditions are met: Flammable substance / mixture, atmospheric oxygen and an effective ignition source. The first two conditions (flammable substance and atmospheric oxygen) form the explosive atmosphere, which can oxidise (burn) completely or to a certain extent with atmospheric oxygen. This process is particularly dangerous in closed or semi-closed spaces. A closed room is usually already designated as a hazardous area if it contains 10l of a flammable substance / mixture. In connection with a potential ignition source, an explosion can occur.

Potential ignition sources can be hot surfaces, mechanical or visible electrical sparks and lightning or static electricity. Especially electronic devices with their own power supply carry the risk of sparking from electrical energy. A malfunction or incorrect operation can, for example, cause the current to be misdirected or overvoltage to occur.

It is therefore important to avoid flammable substances that can form a combustible atmosphere as far as possible or to restrict them as much as possible. In addition, effective ignition sources must be avoided or removed. To what extent this also applies to the use of NFC tags in ATEX environments is explained below.

No sparking due to NFC tags

Although NFC chips themselves usually communicate with electronic devices, they do not have their own power source. NFC chips can therefore not act as an ignition source, neither by their own sparking nor by electrostatic charges of the sheathing. Consequently, NFC chips are also suitable for use in ATEX areas.

Other electronic devices, such as PCs, tablets and smartphones, must be designed in such a way that no effective ignition source can occur even in the event of a fault. Such devices are usually offered in category 2 in ignition protection type and intrinsic safety (standards EN 60079-0, EN 60079-11 and requirements of the 11th ProdSV "Explosion Protection Products"). Since NFC tags are not electronic devices in this sense, these requirements do not apply here.

In summary, there is nothing to be said against the use of passive NFC chips in ATEX environments, provided that the active device used to read the NFC tags complies with the relevant ATEX certifications. However, since such industrial environments often have special requirements, the following is an overview of NFC products for industrial use.

NFC products for the industry

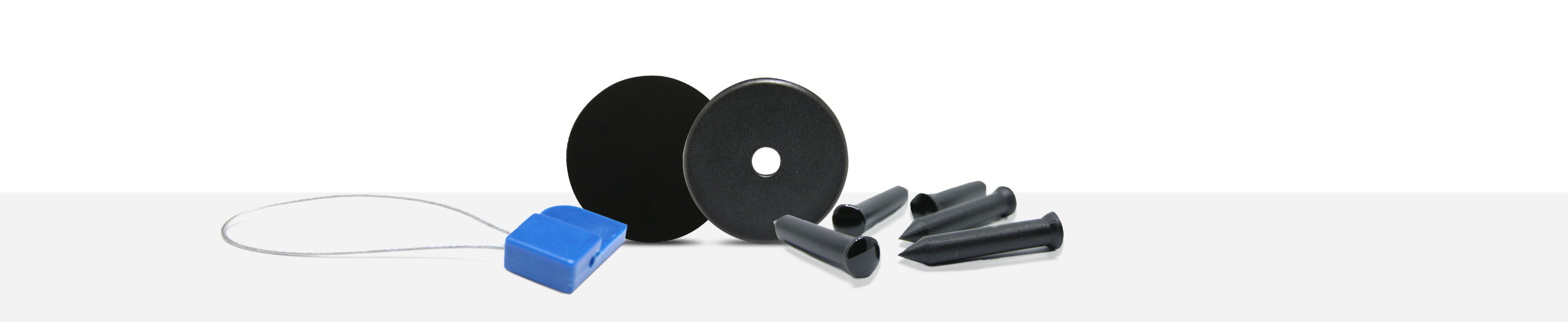

In the following, we describe NFC products that we have specially manufactured for industrial use. Special protection classes ensure extended protection against environmental influences such as chemicals or water. So-called IP protection classes are used. IP protection classes indicate the degree of protection against special environmental influences. For example, IP protection class 68 protects against permanent immersion in water, whereas IP protection class 66 only protects against the ingress of water. Thus, there are certain gradations and protection classes for almost every external influence. Our NFC industrial products have at least IP66 certification.

Here we present our NFC product range for industry.

Conclusion NFC tags for ATEX environments

Because NFC tags operate passively without their own power source, they can be used in ATEX environments and do not represent a potential source of danger. Special industry tags, such as the unique ID of each NFC tag, make it easy and cost-effective to track and inventory batches.

Feel free to contact us, we will also be happy to help you with special and individual inquiries!

Further sources:

- https://www.tuev-nord.de/de/unternehmen/industrie/betreiber/explosionsschutz/

- https://www.ecom-ex.com/de/explosionsschutz/ex-zonen/

- https://www.bgbau.de/themen/sicherheit-und-gesundheit/gefahrstoffe/uebergeordnete-gefahrstoffthemen/brand-und-explosionsschutz/

- https://www.tuv.com/germany/de/explosionsschutzpr%C3%BCfung-und-zertifizierung.html

- https://www.bartec.de/de/downloads/safety-academy/grundlagen-elektrischer-explosionsschutz.pdf

- https://www.bgrci.de/fileadmin/BGRCI/Downloads/DL_Praevention/Explosionsschutzportal/Dokumente/Artikel_Aich_2017-10-13-Smartphones_und_Tablets.pdf